AGVs and AMRs

Intelligente Intralogistik, fahrerlose Transportsysteme (AGV) sowie autonome mobile Roboter (AMR) der neuesten Generation ist die Zukunft der neuen industriellen Revolution. MAIROTEC entwickelt und integriert fahrerlose Transportsysteme (AGV) sowie autonome mobile Roboter (AMR) bzw. – Fahrzeuge für eine wandlungsfähige und flexibel erweiterbare Vernetzung Ihrer Produktion und Lager-Logistik.

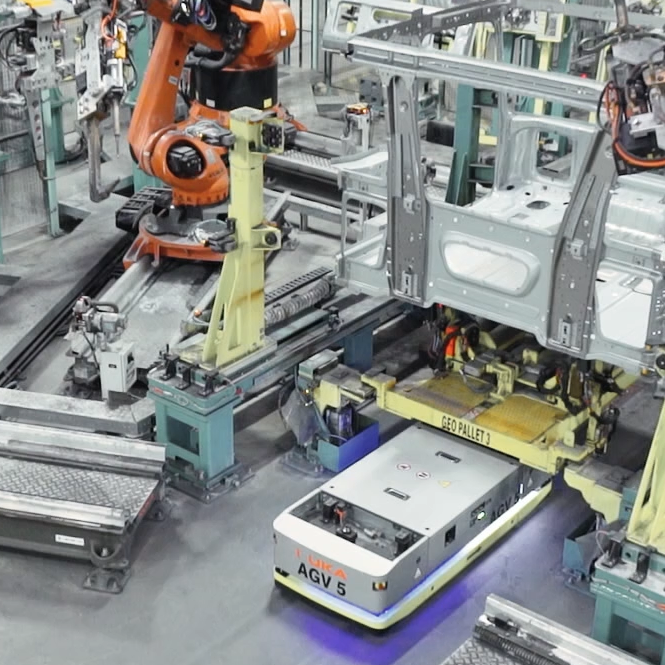

We serve a wide range of different industries with a comprehensive portfolio of efficient automated guided vehicles (AGV). By integrating innovative driverless transport systems, vehicles and robots in the automotive, electronics, warehouse logistics, consumer goods, aerospace and healthcare industries, MAIROTEC has already established itself as a reliable automation specialist for intelligent intralogistics systems.

MAIROTEC - Intelligent robot technology

The advantages of intelligent, driverless transport systems and autonomous robots

As one of the leading automation specialists, MAIROTEC supports manufacturing companies and service providers in the holistic optimisation of their systems, value creation and work processes with fully automated driverless transport systems (AGV) and autonomous robotic systems (AMR). Efficient conveyor systems and robots are revolutionising internal transport and workplaces through transparency and intelligent control.

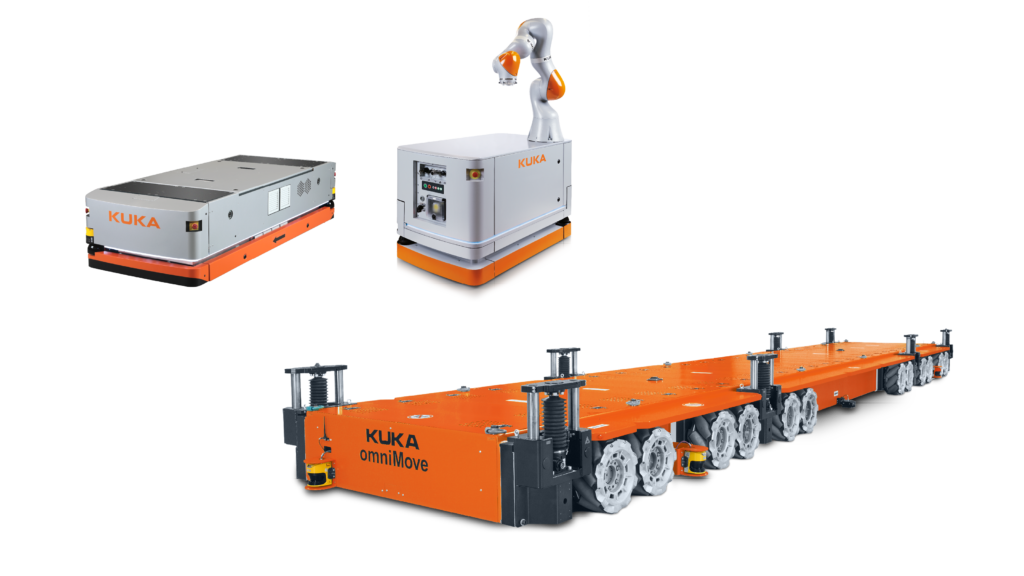

Autonomous transport systems for industrial production processes and more

Digital change, global competition and an increasing number of variants with fluctuating batch sizes demand a high degree of flexibility from production and logistics. The advance of autonomous robots is also a given. The key factor in fulfilling these requirements is the Connectivity of industrial production processes and components. Mobile robots and autonomous conveyor systems are important drivers in enabling fully automated and versatile intralogistics concepts and reliable work processes. MAIROTEC develops and integrates intelligent automated guided vehicles (AGV), vehicles and robots (AMR) that fully automate the intralogistics of your production and a variety of work processes

Advantages of intelligent solutions from MAIROTEC

Faster order picking

Virtual solutions in order picking make it possible to simulate and emulate line processes of AGV applications. This allows picking processes to be optimised by driverless transport systems and autonomous robot systems. Virtual training can also be used to reduce the error rate during order picking.

Reduction in investment and operating costs

The guidance control system based on artificial intelligence navigates the AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robots) on ad-hoc calculated routes for maximum efficiency and capacity utilisation. This allows the number of vehicles deployed to be reduced. As a result, investment and operating costs can be significantly reduced.

Shorter response times

By using our intelligent control system, which controls the driverless transport vehicles and autonomous robot systems within the production environment, the internal material flow becomes transparent. Driverless transport systems make it possible to react more quickly to changes in demand, make scheduling more precise and automatically ensure that deadlines are met.

Weniger Transportschäden & Ausfallraten

The use of driverless transport systems enables free transport routes for vehicles and therefore automatically improves safety in production. The safety features of AGVs and their navigation by an intelligent guidance system reduce transport damage and failure rates. The flexibility and efficiency of your production is significantly increased.

You have a task - we have the intelligent solution.

The variety of solutions from MAIROTEC

In addition to transport vehicles and autonomous mobile robot systems, we also offer solutions in the areas of cleaning, collaboration with employees, workplace support, small parts provision by service robots and much more.